1941 Ford Truck

Article & post-build photos by Larry Crain

Build photos by Richard Broyles

At one time or another almost everyone in the automotive enthusiast world has dreamed of building a vehicle that would stop people in their tracks and say “Wow” or other colorful words. For many, this is just a dream or one that was just partially fulfilled for one reason or another. To dream this type of dream is to start down a road filled with many curves, potholes, crossroads and delays. Often it’s a journey to find out if you have what it takes to finish.

One such person is Richard Broyles of Jonesborough, TN who started down such a road about 7 years ago with the lofty goal of building a vehicle in his home shop that would try to win the much sought after Ridler Award at the Detroit Auto Rama. Richard has built many cars during his life and one previous car that competed against the show circuit cars. But as good as that car was, it was not built to be a contender for the Ridler. For this project, Richard would have to dig deep into his imagination and use all of his many talents to build his American Dream. This project was built with winning the Ridler in mind but also in the hopes that it would inspire others to accomplish what some might think you cannot.

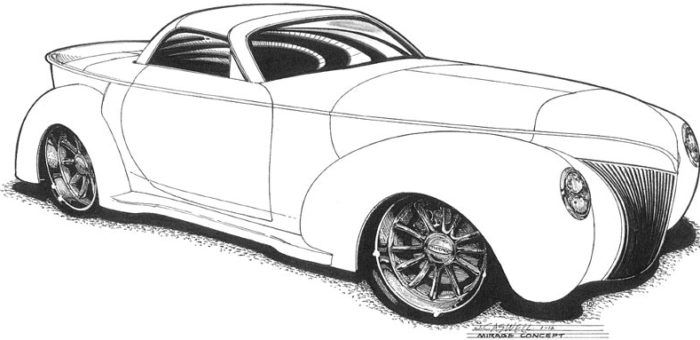

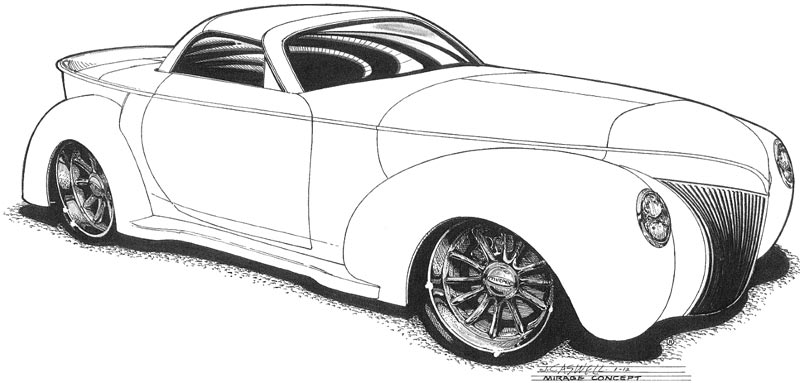

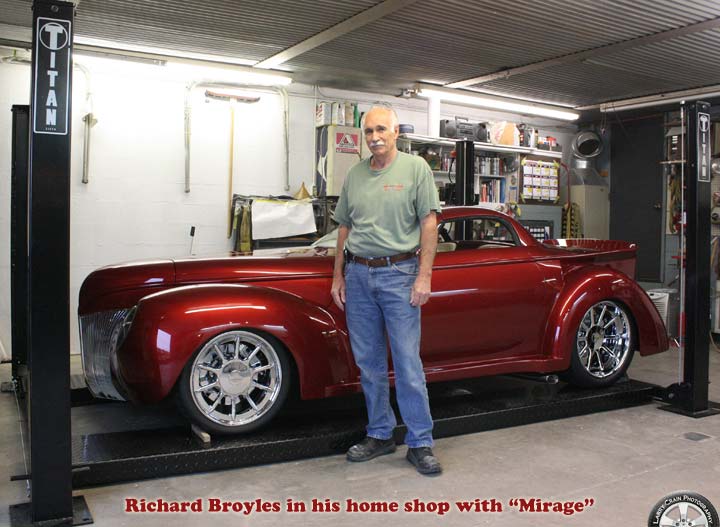

Richard’s project titled Mirage started out as nothing but a 1941 Ford truck cab with fenders and a whole lot of imagination. The idea was to build a roadster style fat-fendered truck that looked to the past as well as to the present. Every bit of this truck came from Richard’s imagination, which he then transformed into the custom parts of steel or aluminum that flowed into this beautiful piece of rolling automotive artwork. To begin this project Richard took his ideas to local artist Jim Caswell to work up a concept drawing that would help him focus on what the finished vehicle would look like.

Richard put a lot of hours into just the metal forming aspect of this body and chassis making sure that each panel flowed into the next whether it was on the exterior of the body or the underside that would be mostly seen by judges. Attention to detail and design is what makes a truck or car worthy of competing on the level that Richard was shooting for. Starting at the Ford inspired Alumicraft grill all the way back to the hand crafted bed, every part had many hours of thought put into it before the first piece of metal was bent. When you talk about fabricating a complete vehicle this has to include the numerous parts and pieces that he made out of aluminum stock and machined into just about every part, which then has to be polished or chromed on the truck. Functionality is another aspect that has to play a big part in a build, and it does on this truck. From the retractable hardtop to the butterfly style opening hood and deck lid, every part of the truck that you might think is just another pretty show piece does actually work and serve a purpose.

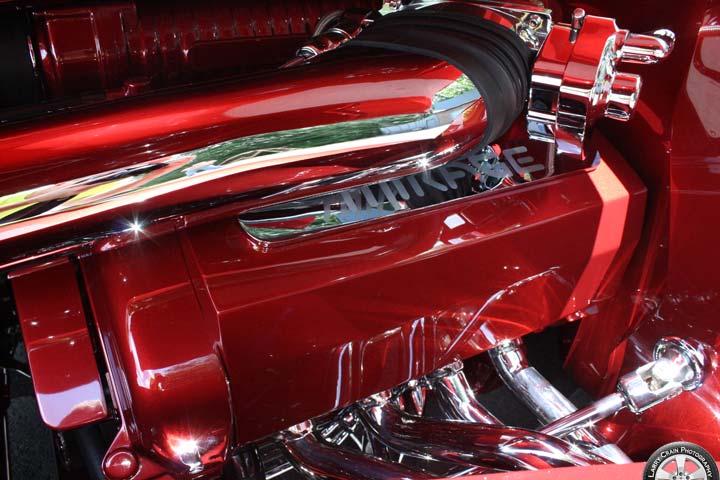

A lot of thought was put into what color would really show off the curves, body lines and flow of the body, and Richard found a stock factory color then had several changes made to the formula that would make it unique to this vehicle. The paint on the truck was then specially formulated by Axalta/Dupont and is identified as “Sunset Mirage” Chroma Premier base coat, top coated with 72200S Chroma Premier Clear. The base coat was applied over Epoxy DTM primer sealer base with 33403S Chroma Premier primer. The end result was an incredible color with brilliance and depth that has to be seen to be believed. Body prep and painting was an extremely challenging process due to the unusual body configurations. The many obstacles and pitfalls during this stage were overcome through the hard work of Richard and Ron White and Jon Watts. Richard, along with the help of Jack Whitson, did the final assembly, fit, finish, final stages of buffing and then detailing.

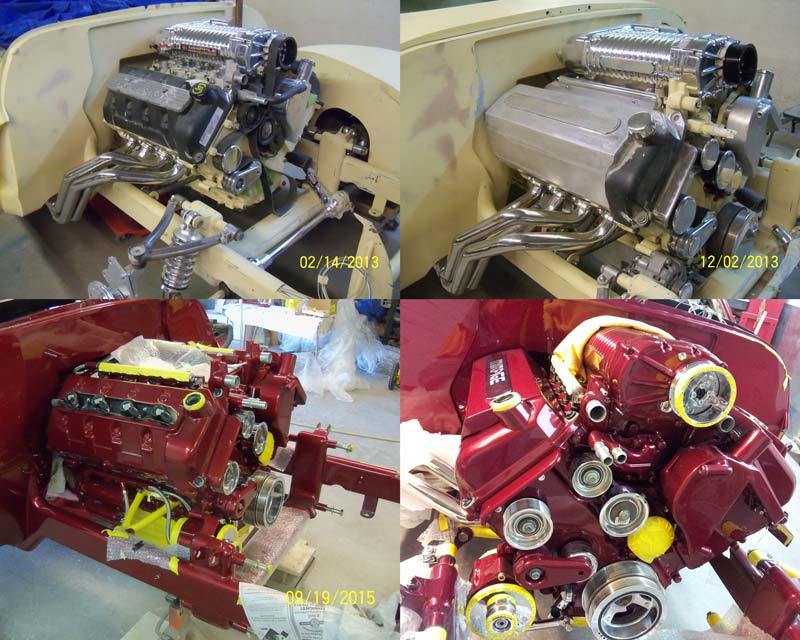

For Richard this build also had to include a drive-train that would reflect the old school look and showcase the new power available in today’s vehicles. So he found a very serious Ford Shelby 5.4 DOHC engine with only test miles on it, smoothed the block, and painted it to match the body. All of the unnecessary brackets and mounts were removed to give it the clean, uncluttered look of old. The custom valve covers were fabricated to conceal all of the electrical components while complimenting the legendary Ford DOHC stylish look. The Supercharger is a Whipple 4.0 Crusher with a mono blade throttle body that has had the openings shaved, refined or welded to create a very smooth and statuesque body. Of course Richard had to go new school and use a Ford Racing computer that has race calibrations for the supercharged 32-valve 5.4 DOHC engine. Completing this unique engine are the headers and an exhaust system that, once again, is a head nod to old school and new. It is a combination of a Borla custom built stainless one-piece over the frame-designed headers with Stainless Specialties silencers transitioned to Borla oval side exit pipes. The transmission for this hot rod had to be a manual but instead of the old style 4-speed Richard went with a Tremec 6-speed that could more than handle the horsepower and rpm’s that the motor would turn out. The rear differential is of course a retro-look Winters Championship Quick Change 10” big HP series that runs Strange Axels. The steel tubes have been modified with outer bearing housings, the case has been smoothed and the oval center cover turned into a show piece that features 12 point case fasteners and the whole unit sits on one-off chromed suspension mounts.

The front and rear suspensions are another of Richard’s design and idea that is a radical one-off unique arch design that was built by Scotts Hot Rods. The front steering rack is from Chassis Works that features novel trim pieces that enhance it to a higher level of appearance. The brakes are from Wilwood that feature modified brackets, smoothed calipers, hats welded and smoothed, rotors chromed and veins powder coated and the rear brakes have an integral parking brake. Finishing off the rolling chassis and complimenting the coachwork are a set of one-off 3-piece wheels Richard thought up and designed that were magnificently brought to life by Intro Wheels. The wheels are 10 spoke 18x7 on the front and 20x10 on the rear that gives the truck a serious stance in the hot rod style.

The interior of the truck shows the continuation of the outsides reveal/body accent line by flowing seamlessly across the painted interior doors, dash, console and onto the seat surrounds. The continuity of this hand formed steel reveal ties the contours of the interior to the exterior so with doors open or closed everything flows together. The interior showcases the metal working skills of Richard starting with the dash, console and seat frames that were are all hand-fabricated steel. The steering column is a stainless steel unit from Flaming River, which has been painted to match the interior & exterior. The column drop is another owner-fabricated piece that has been chromed while the steering wheel is an Intro piece that carries over the owner designed idea for the wheels on the chassis that were also built by Intro. The center mounted LED gauge cluster surround trim is hand formed aluminum that has been chromed. Gauges are from Classic Instruments that have been reworked by Richard to fit into the custom gauge panel. The console mounted shifter is a Ford short throw that has been heavily modified for this application and topped off with another home shop fabricated shifter handle and knob that were both constructed from aluminum then chromed. The emergency brake is a functional integral part of this standard shift vehicle with the one-off chrome handle and release button all connected to the Wilwood brake assembly by Lokar stainless braided cable assembly. The shifter and emergency brake surround trim is a custom piece made Larry Palmer and that was chromed by Advance Plating. The console is home for switches that service many electrical components around the car. All of the switch covers and button covers are owner-made pieces from aluminum that have been chromed. The oval pedal assemblies are Lokar pedals modified by the owner and that have been chromed. Steve Holcomb of Pro Auto Interiors in Knoxville, Tennessee performed the custom interior work. The interior leather work is an entirely one-off design of done in a beautiful leather called Magnolia produced by Wallsdorf and accented with DeModa Cobra Vino from Garrett Leather. The carpet that Pro Auto Interior chose to compliment this beautiful interior was a Mercedes Benz Velour Middle Red.

After all of the years of hard work Richard loaded up his truly unique roadster truck and headed to Detroit in February of 2016 to see if his “American Dream” could come true in the shape of the ultimate award: “The Ridler”. The vehicles he was to compete against were high dollar pro-shop built machines that had been built for the very same reason as his: to make the Great 8 and then bring home the Ridler. There have only been a few owner-built vehicles to make the Great 8 and fewer to win the Ridler.

While Richard’s truck did not bring home the Ridler, it did bring home a Great 8 award, which is quite an achievement in itself when you look at the level of perfection the vehicles Richard was up against. This also showed that an owner-built vehicle could compete against professionally built competition, win a Great 8 Award and have a shot at the Ridler.

Richard proved in Detroit that the “American Dream” is alive and well in the everyday person’s garage. He really hopes that what he accomplished will inspire other builders, no matter their age or where they come from, to set a goal, follow it through and see their “American Dream” come true.

Richard sends out a big thanks to all of these manufacturers and shops for all of their technical support while he figured out how to use or adapt their products into building his “American Dream”. I also want to thank Richard for the early build photos of which he has several hundred that we had to pick from.